Modern

automation, robotics, electric vehicles, and industrial machinery are all

supported by electric drives.

Effective drive control enhances precision, performance and energy savings. This blog aims to provide you an in-depth overview of the various methods for electric drives, based on their principles, types, advantages, and typical applications.

What Are Electric Drives?

The drive consists of an electric motor, power electronic converters, sensors and algorithms to regulate the speed, torque and position of the motor as demanded by the application. This includes the uses such as:

• Industrial automation

• Electric vehicles (EVs)

• Home appliances

• Robotics and CNC machines

Need for authority in Electric Drives

Fundamentally, electric motors operate under the laws of electromagnetism, but, in practical terms, one must:• Impose accurate speed-torque profile

• Assure stability with changing load

• Consume energy optimally

• Start and stop smoothly

• Protect against overcurrent, over speed, and overheating

Types of Managing Strategies

Managing methods

for electric drives are generally classified as open-loop and closed-loop.

Let's discuss them in detail.

1. Open-Loop Control

The leaves of

signal is provided with no feedback from the motor, in open-loop systems. It is

inexpensive but simple and has no accuracy and disturbance rejection.

Example: Simple fan speed authority using a potentiometer.

Advantages:

• Design is

simple

• It is

economical

• No sensors

needed

Disadvantages:

• No

compensation for load variation

• Inaccurate power

of speed

2. Closed-Loop System

A closed-loop sensor watch on motor's operation and automatically

adjusts input, allowing everything to work effortlessly and more accurately.

a) Scalar Control

It guarantees fixed voltage-to-frequency ratio for induction motor system.

Advantages:

• Easy to implement

• Ideal for low-performance applications

Disadvantages:

• Limited dynamic performance

• Low torque power

Applications:

HVAC systems, pumps, blowers

b) Vector (Field-Oriented Control - FOC)

This sophisticated

technique separates torque and flux power in AC motors, just like for DC

motors.

Advantages:

• High dynamic performance

• Torsion and speed precise

authority

Disadvantages:

• Costly and requires

sophisticated algorithms and sensors

• More expensive

Electric vehicles, robotics, CNC machines

c) Direct Torque Control (DTC)

In

this technique, torque and flux are authority directly without any modulation

techniques or coordinate transformation.

Advantages:

• No

current regulators required

•

Fast dynamic response

Disadvantages:

•

Complex to implement

•

Torque ripple is high

Applications:

Traction systems, industrial drives of high performance

Other Advanced Techniques

1. Sensor less Control• Removes the necessity for mechanical sensors by approximating rotor position/speed.

• Reduces system cost and increases reliability.

2. Model Predictive Control System (MPC)

• Using machine learning and AI for adaptive, smart power.

• Highly accurate but computationally intensive.

3. AI-Based Level System

• Employing machine learning and AI for adaptive, smart authority.

• Applicable for complex, nonlinear systems.

Comparison of Control Strategies

|

Control Type |

Complexity |

Performance |

Cost |

Application Area |

|

Open-Loop |

Low |

Low |

Low |

Fans, basic pumps |

|

Scalar Control |

Medium |

Moderate |

Medium |

HVAC, conveyors |

|

Vector Control |

High |

High |

High |

EVs, robotics |

|

DTC |

High |

Very High |

High |

Traction, industrial |

|

AI-Based Control |

Very High |

Adaptive |

High |

Research, smart systems |

Engineering Project Ideas Based on Electric Drive

Manage

1. PID vs FOC level for BLDC Motors2. Sensor less Speed of Induction Motor Using DSP

3. Fuzzy Logic-Based Speed leavel for EV Drive System

4. Simulation of V/f Control of 3-Phase Induction Motor using MATLAB

5. IoT-Based Real-Time Monitoring of Charged Drive Systems

Conclusion

The selection of a control method for electric drives is based on the type

of motor, requirements of the application, cost factors, and the desired

performance. Scalar is an approach that only magnitude whereas vector and DTC

take into consideration the torque support angle as well as the motor magnitude

and direction of motion. As sensor less and AI-based techniques are gaining

popularity, the future of power drives is inclined toward intelligent,

efficient, and autonomous systems.

Want to know more about electric drives and control

systems?

Look at our expert project assistance at TakeoffProjects – where we bridge the gap between theory and practice!

Power Electronics for Smart Grids: Enhancing Efficiency

Power Electronics for Smart Grids: Enhancing Efficiency  Introduction to Control Systems: Principles and Applications

Introduction to Control Systems: Principles and Applications  Electric Drives: Fundamentals & Key Components

Electric Drives: Fundamentals & Key Components  Applications of Power Electronics in Renewable Energy Systems

Applications of Power Electronics in Renewable Energy Systems  Designing Efficient Power Converters: Tips and Techniques

Designing Efficient Power Converters: Tips and Techniques  Advances in Power Semiconductor Devices

Advances in Power Semiconductor Devices  Power Electronics: Key Concepts and Applications

Power Electronics: Key Concepts and Applications  Cybersecurity in Power Systems: Protecting Critical Infrastructure

Cybersecurity in Power Systems: Protecting Critical Infrastructure  The Evolution of Power Transmission: From AC to HVDC

The Evolution of Power Transmission: From AC to HVDC  Impact of Energy Storage on Power System Management

Impact of Energy Storage on Power System Management  Load Flow Analysis : Techniques and Applications in Power Systems

Load Flow Analysis : Techniques and Applications in Power Systems  Microgrids: Enhancing Resilience and Efficiency in Power Systems

Microgrids: Enhancing Resilience and Efficiency in Power Systems  Innovative Technologies in Power System Protection

Innovative Technologies in Power System Protection  Challenges and Solutions in Power System Stability

Challenges and Solutions in Power System Stability  Final Year Electrical Engineering Project Ideas for College Students

Final Year Electrical Engineering Project Ideas for College Students  The Role of Renewable Energy in Modern Power Systems

The Role of Renewable Energy in Modern Power Systems  Smart Grids: Revolutionizing the Future of Power Systems

Smart Grids: Revolutionizing the Future of Power Systems  Automated Power Factor Correction: Improving Energy Efficiency

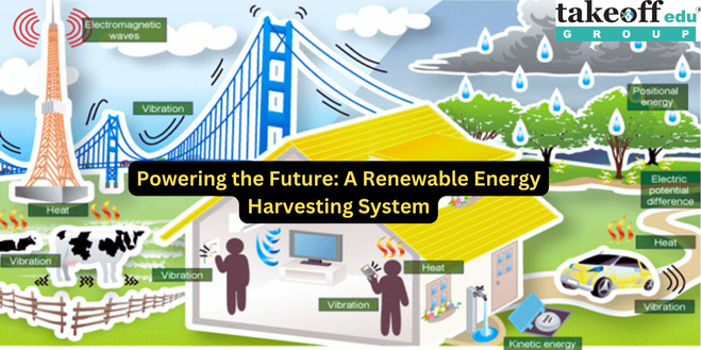

Automated Power Factor Correction: Improving Energy Efficiency  Powering the Future: A Renewable Energy Harvesting System

Powering the Future: A Renewable Energy Harvesting System  Smart Grid Solutions: Enhancing Electrical Distribution Efficiency

Smart Grid Solutions: Enhancing Electrical Distribution Efficiency  Electric Vehicle Charging Infrastructure Design and Implementation

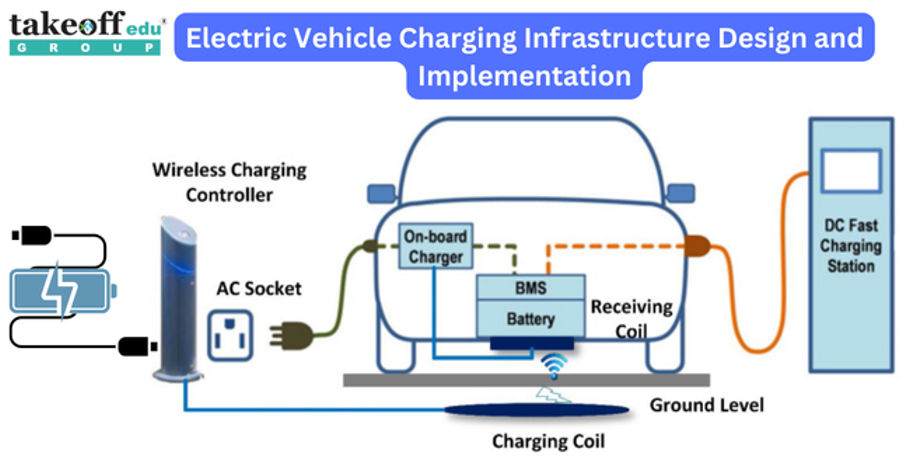

Electric Vehicle Charging Infrastructure Design and Implementation  Integration of Renewable Energy Sources in Microgrids

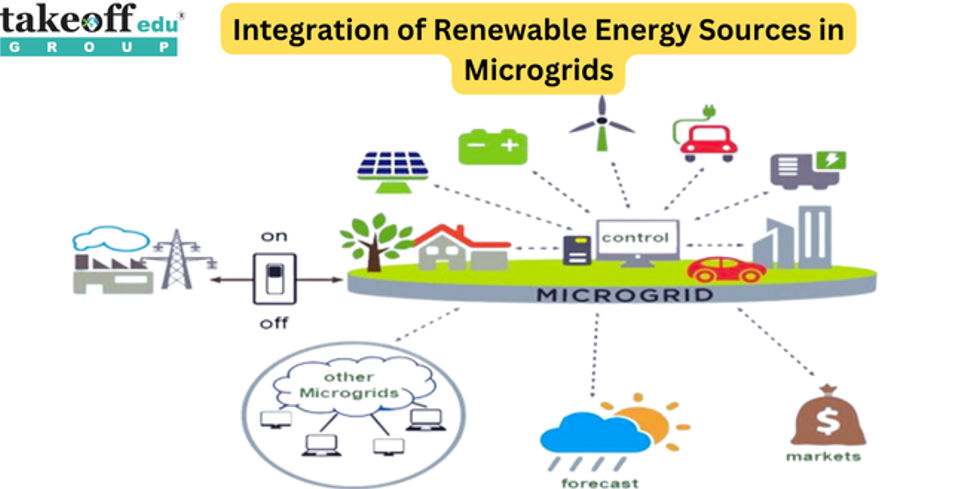

Integration of Renewable Energy Sources in Microgrids  Electrical Projects Engineering Students

Electrical Projects Engineering Students  M.Tech Thermal Engineering Projects

M.Tech Thermal Engineering Projects  IEEE Projects for Electrical Engineering

IEEE Projects for Electrical Engineering  Mini Projects for EEE

Mini Projects for EEE  Mini Projects for Electrical Students

Mini Projects for Electrical Students  Top Electrical Projects for Final Year Students

Top Electrical Projects for Final Year Students  10 Interesting Projects for Electrical Engineering Students 2022

10 Interesting Projects for Electrical Engineering Students 2022  7 Trending Power Systems Based Projects for EEE

7 Trending Power Systems Based Projects for EEE  Top 10 Power Electronics Projects for EEE

Top 10 Power Electronics Projects for EEE  Top 16 Electrical Engineering Projects

Top 16 Electrical Engineering Projects

Paper Publishing

Paper Publishing