Power electronic systems serve as the core foundation of numerous modern technologies from renewable energy systems, electric vehicles, industries automation to aerospace. Along with the enhancement in performance and power density, heat dissipation seems to come up with its own challenges. Efficient thermal management includes beyond all these aspects; it is requirements of reliability, life, and safety. Check out this blog, which gets into the best practices for dealing with thermal management of power electronics and how it greatly matters in today's high-performance applications.

🔥 Why Thermal Management Matters

Heat is a by-product of switching losses, conduction losses and inefficiencies associated with the power electronic devices such as IGBTs, MOSFETs and diodes. Such conditions, if unattended, may result in elevated temperatures leading to:

- Damage of power devices

- Failures of associated components

- Early aging of the entire electric system

We need thermal design with variable layout with the aim of being flexible, efficient and cost saving and of maximizing geometrical optimization

✅ Best Practices for Thermal Management

1. Accurate Thermal Modeling

Remember that you first begin by simulating well. You must be using tools-cum-ANSYS. COMSOL and LTspice are essential tools for analyzing heat generation measurements, flow modeling, and predicting design hot spots before lab testing.

2. Optimize PCB Layout

PCB design significantly impacts heat dissipation, with thick copper layers, thermal vias, and evenly distributed power components aiming to reduce heat concentration.

3. Use High-Quality Thermal Interface Materials (TIMs)

TIMs serve the function of filling minute air gaps found between mating surfaces, thus making thermal conduction from one surface to another more efficient. Choose TIM materials with high thermal conductivity, and ensure that they are applied correctly.

4. Heatsinks and Heat Spreaders

Heatsinks are the traditional passive cooling remedy. To make them work better:

• Select heatsinks with a larger surface area.

• Shape the fins according to the airflow pattern (pin-fins work well for turbulent flows).

• To achieve optimal contact, apply thermal grease or thermal pads.

5. Active Cooling (Fans, Liquid Cooling)

While passive is not good enough, active cooling methods come into play:

• Fans are used to increase air movement, which in turn enhances heat transfer from heatsignks.

• Liquid cooling comes in handy for systems with high power density as it has better thermal conductivity than air.

6. Thermal Sensors and Real-Time Monitoring

So, temperature sensors to monitor device or system temperature will be integrated with appropriate software controls to generate alarms or reduce power supply under over temperature conditions.

7. Derating and Power Cycling Considerations

Don't expose components or electronic devices to extreme thermal limit. Enrich Reliability: Derate the component or run it under maximum ratings. Also, design for thermal cycling (repeated heating and cooling): this will degrade the materials in the long term.

🌡️ Thermal Management in Emerging Technologies

It becomes increasingly critical for thermal management to enable the use of wide-bandgap semiconductors such as SiC and GaN. These devices have high power switching capabilities at high voltages and generate a higher surface temperature under a very small footprint.

In high-end applications, there is a trend toward the progression of advanced technologies, i.e. vapor chambers, thermoelectric coolers and phase-change materials.

🔧 Conclusion

Thermal management is no longer simply a consideration that adds into design after it is completed-in fact, it is a significant part of power electronics design itself. If these best practices are established early on in the development process, an engineer can expect superior performance instilled in a safe and long-lived system. Be that electric vehicles, solar inverters, or drives for industrial applications, temperature is the independent foe. An intelligent machination to control the same happens to be the determiner of productivity.

Wireless Power Transfer: The Future of Power Electronics

Wireless Power Transfer: The Future of Power Electronics  Energy Efficiency in Power Electronics: Trends and Solutions

Energy Efficiency in Power Electronics: Trends and Solutions  The Role of Power Electronics in Electric Vehicles (EVs)

The Role of Power Electronics in Electric Vehicles (EVs)  High-Frequency Power Electronics: Innovations and Challenges

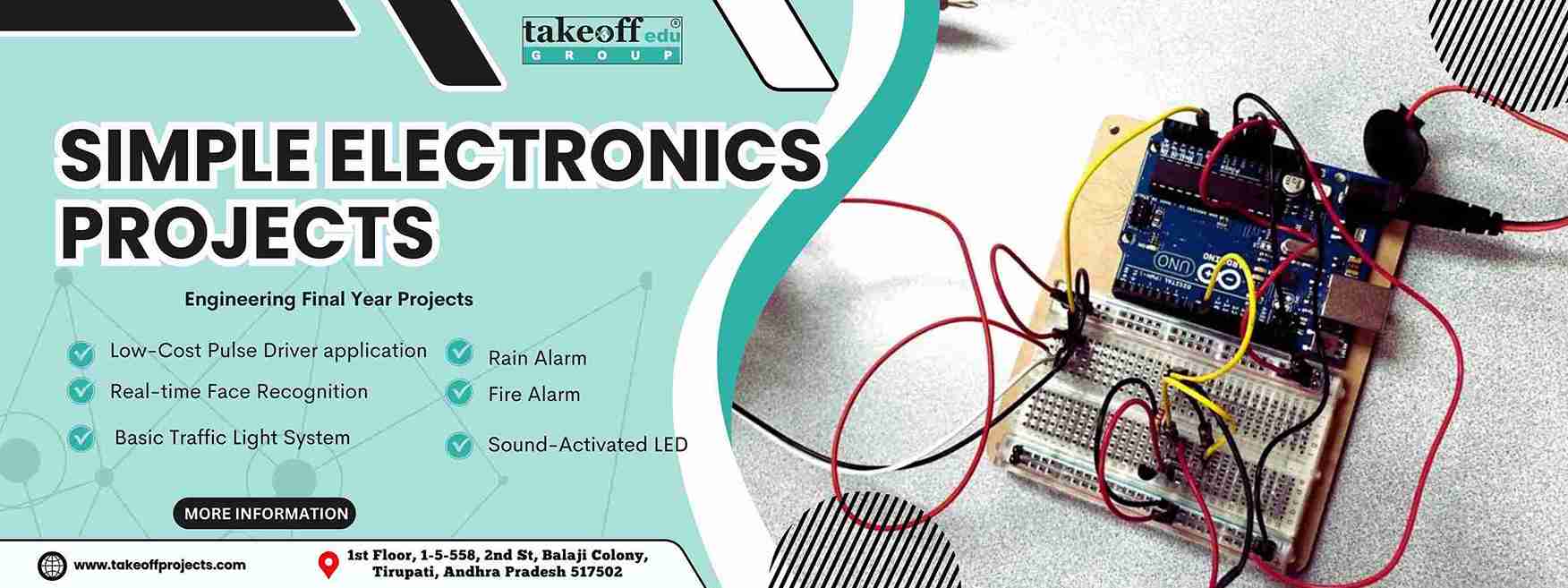

High-Frequency Power Electronics: Innovations and Challenges  Simple Electronics Projects

Simple Electronics Projects  Wireless Communication Projects for Engineering Students

Wireless Communication Projects for Engineering Students  Electronics Projects for Engineering Students

Electronics Projects for Engineering Students  M.Tech Electronics Projects

M.Tech Electronics Projects  IEEE Project Papers for ECE

IEEE Project Papers for ECE  IEEE Projects for ECE

IEEE Projects for ECE  Latest Projects on Embedded Systems for ECE

Latest Projects on Embedded Systems for ECE  ECE Final Year Project Ideas 2022

ECE Final Year Project Ideas 2022  Latest Mini Projects for ECE

Latest Mini Projects for ECE

Paper Publishing

Paper Publishing